RG Series

The RG Series

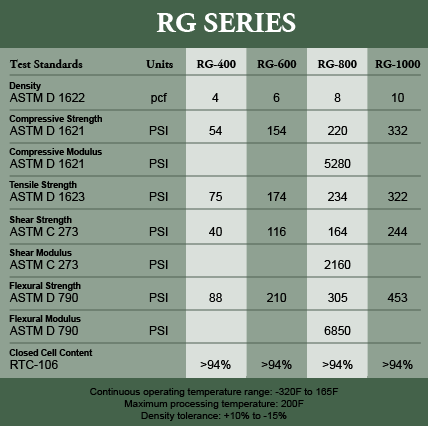

Our foam is available in a wide range of densities from 2.5 PCF to 8 PCF. This series can be cut in thicknesses from 3/8″ to 6” and can also be grooved, perforated or double cut for an additional cost.

Thicknesses greater than 6 are multi-piece construction and are available in plain sheet stock only.

Primary Features

- Closed cell foam – eliminates water absorption

- Good dimensional stability

- Compatible with polyester, vinyl-ester & epoxy resin systems

- Processing temperatures up to 200F

- High strength to weight ratio

Accepted Applications

- Marine – hulls, decks, stringers & bulkheads

- Transportation – cabs, sleeper floors & RV bodies

- Architectural – carving and milling foams

- 5 axis router – milling foam

Fiberglass Reinforced Panels (FRP)

Produced using REC’s pneumatic presses. The presses use 80-100 PSI thereby producing a smooth, straight panel without wrinkles or resin feed and groove lines as well as good strength to weight ratio.

- REC urethane foam core or core to customer’s specifications

- Available with customer specified fiberglass cloth for “skins”

- Available with different “skins” on top and bottom

- Available with polyester, epoxy or vinyl ester resins

Accepted Applications

- Marine – Decks & bulkheads

- Transportation